The Ultimate Guide To Inventory Management

Table of ContentsSome Known Factual Statements About Inventory Management Rumored Buzz on Inventory ManagementThe 9-Second Trick For Inventory Management7 Simple Techniques For Inventory Management

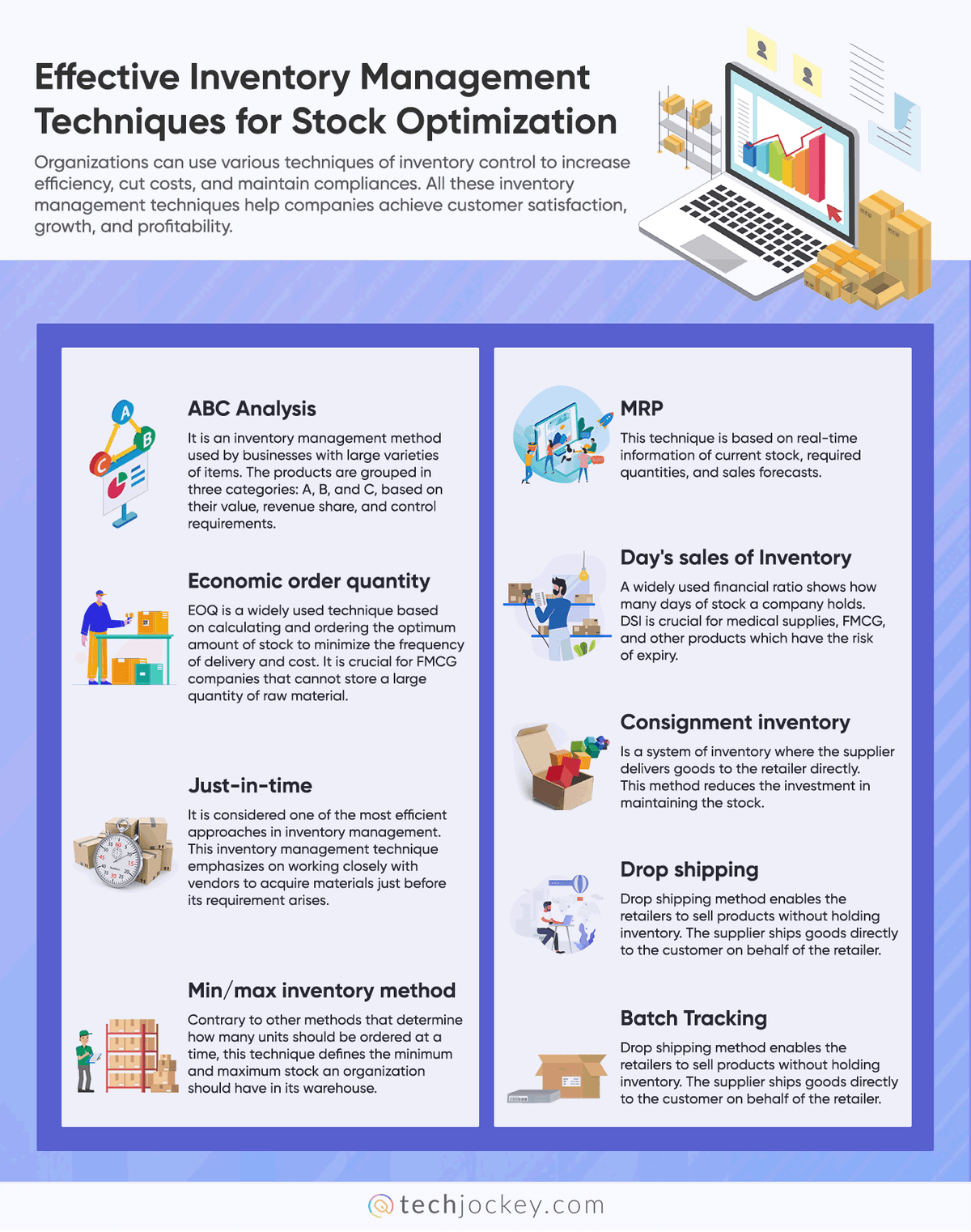

There are 2 main methods of tracking supply: regular as well as continuous. The major distinction between these is exactly how frequently data is updated. Despite exactly how frequently you track stock, you might wish to use one of the complying with inventory monitoring methods: ABC Evaluation, ABC (Always Better Control) Evaluation is inventory administration that separates different items right into three groups based upon pricing and is divided into teams A, B, or C.The products in the B group are relatively more affordable compared to the A category. And also the C group has the most inexpensive products of all three. EOQ Model, Economic Order Quantity is a method made use of for preparation as well as ordering an order quantity. It includes deciding regarding the amount of stock that need to be positioned in stock at any kind of given time. Inventory Management.

FSN Method, This method of stock control refers to the process of keeping an eye on all the products of supply that are not used often or are not called for all the time. They are after that classified into 3 various classifications: fast-moving inventory, slow-moving supply, and also non-moving stock. JIT Method, In the nick of time supply control is a procedure used by makers to control their stock degrees.

Getting The Inventory Management To Work

VED Evaluation, VED is a technique made use of by companies to regulate their supply. It generally refers to the monitoring of crucial and preferable extra parts. The high degree of inventory that is needed for manufacturing usually validates the reduced stock for those parts. Among the most crucial variables that a company ought to think about is the precision of the information offered in its stock databases.

Wrike is a task administration remedy that can help you do precisely that. With Wrike's item monitoring devices, you can handle all of your product group's activities in one area as well as get one of the most out of every project. Wrike's product launch automation assists accelerate product launches with a streamlined method.

Inventory management attempts to effectively simplify stocks to stay clear of that site both excess and also scarcities. Four significant supply administration techniques consist of just-in-time administration (JIT), products need planning (MRP), financial order quantity (EOQ), and also days sales of stock (DSI).

A scarcity of supply when and also where it's needed can be incredibly destructive. At the very same time, stock can be thought of as a responsibility (if not in an accounting feeling).

Knowing when to restock inventory, what quantities to purchase or generate, what price to payas well as when to market as well as at what pricecan easily ended up being complex choices. Local business will certainly often keep track of supply by hand as well as determine the reorder points and also quantities making use of spreadsheet (Excel) solutions. Larger businesses will make use of specific enterprise resource preparation (ERP) software application.

Inventory Management Fundamentals Explained

Suitable inventory monitoring techniques differ relying on the sector. An oil depot is able to save huge amounts of stock for extended periods of time, allowing it to await need to get. While keeping oil is expensive as well as riskya fire in the U.K. in 2005 resulted in numerous pounds in damage and also finesthere is no danger that the supply will certainly ruin or head out of style.

For companies with intricate supply chains and producing procedures, stabilizing the dangers of supply excess and lacks is particularly tough. To accomplish these balances, companies have actually developed several techniques for supply administration, including just-in-time (JIT) as well as materials demand preparation (MRP). Some business, such as financial solutions companies, do not have physical stock as well as so should depend on service hop over to these guys process management.

Supply has to be literally counted or determined before it can be placed on a balance sheet. Finished goods are finished items readily available for sale to a firm's customers. Depending on the kind of organization or item being assessed, a company will utilize various inventory monitoring methods.